- 爱游戏ayx守望先锋

- 目录

- 新闻与趋势

- 展览

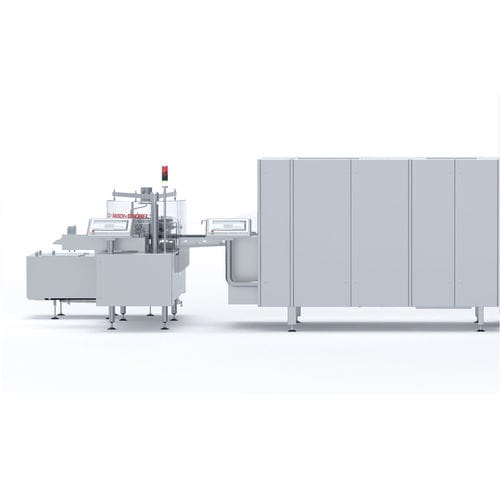

隧道灭菌器DHT系列

过程

热空气

瓶

添加到收藏夹

比较这个产品

特征

- 实验室/过程

- 过程

- 灭菌方法

- 热空气

- 其他特征

- 隧道

- 应用程序

- 瓶,为制药业所用

描述

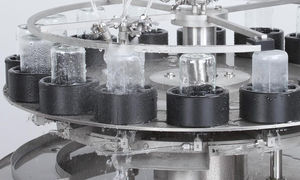

DHT系列的灭菌隧道使用低湍流垂直气流对玻璃容器进行干燥、灭菌和去热原。灭菌级过滤器或一体化高效微粒空气过滤器(HEPA过滤器)不需要在排气侧进行任何密封。灭菌区的特殊热气体过滤器在所有操作条件下(甚至在预热和冷却阶段)产生无尘室a级大气。隧道有多层保温层,以防止热量流失和最大限度地提高能源效率。•低湍流,垂直气流,实现最佳的传热•精确维护生产参数•温和的容器加热•高能效性能•B+S热气体过滤器,过滤器寿命长•方便集中操作•药物设计可选额外配置•横向传送带,带传输机构,用于隧道进料稳定的容器•加热计时器,用于操作前预热•洁净室分区•预热和加热中的特殊鲍许+Ströbel热空气过滤器cooling zones • Vane wheel anemometers for air velocity measurement in the pre-heating, sterilizing and cooling zones, with display on the operating panel or recording on a multichannel process recorder • Equipment to monitor the differential pressure between the cleanroom and the cooling zone • Equipment to monitor the max. dwell time of the containers in the high-temperature environment, with discharge of processed containers to the machine downstream (DHT 4432/DHT 5732/DHT 5764) • Heat exchanger (for cooling the circulating air in the cooling zone)