- 公司

- 爱游戏ayx守望先锋

- 目录

- 新闻与趋势

- 展览

PP挤出机

宠物

个人电脑

单螺杆

添加到收藏夹

比较这个产品

特征

- 处理材料

- 适用于PP, PET, PC

- 螺钉数量

- 单螺杆

- 其他特征

- 紧凑,发泄

- 输出

-

最小值。0 kg/h (0 lb/h)

马克斯。2000 kg/h (4,409.2452 lb/h)

- 螺杆直径

-

最小值。30mm(1英寸)

马克斯。250毫米(10英寸)

描述

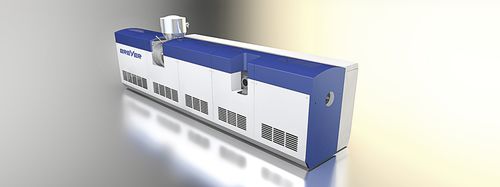

任何挤出系统的核心元素之一是并仍然是挤出机本身。从一开始,布雷耶的重点就是质量和复杂的技术。布雷耶挤出机设计为单螺杆式,运行效率高。大多数常见的热塑性树脂都可以加工。可提供以下尺寸:螺杆直径(mm): 30、35、45、60、75、90、105、120、150、180、200、250 mm输出范围(kg/h)取决于挤出机尺寸,可达到2000 kg/h。我们的专长是通风挤出机。他们运行非常经济,因为耗时和能源密集型的树脂预干燥不存在。排气将残留单体的比例降至最低,并有效地对原料进行除湿。在顶部,我们的挤出机显示出较高的比产量。他们的工作仍然可靠,而其他机器需要已经预干燥的材料。 Save your energy BREYER extruders are designed to operated with low energy use. All e-cabinets are equipped with Siemens control unit. The comfortable operations works via touch-display. Further equipment: solid state relais, single-current measuring, for each zone, longlife cearamic heater bands (with quick exchange connection), safety temperature control and detailed error evaluation. We are using AC drives as main drive for the extruders. On request, extremely quit running watercooled motors are available. High customer advantage Brushless, maintenance free drive technique high specific output lowenergy consumption effective venting no resin drying necessary compact machine design

目录

布雷耶挤出机方案

2

页面