- 爱游戏ayx守望先锋

- 目录

- 新闻和趋势

- 展览

流化床干燥器成品

热空气

气体

空气

添加到收藏夹”

这种产品比较

特征

- 技术

- 流化床,热空气

- 应用程序

- 气体,空气

- 其他特征

- 不锈钢

描述

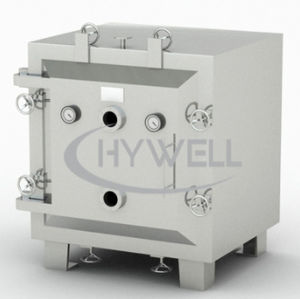

原则的新鲜空气是由两个或三个过滤器过滤,然后进入加热的加热系统。加热后,热空气进入干燥室和炸毁材料碗的定期监测,让材料流化条件后,这段时间,材料是干的。当客户使用这台机器,他们可以设置程序和参数根据流程需求,然后启动机器。结构1。入口摘要入口摘要由初级过滤器(G4)、过滤器(F8),高效过滤器(H13)和加热器和精确的温度控制。入口气流速度和压力是可变的和可控的。加热器,它可以是蒸汽散热器、电加热器、天然气炉等等。2。主体结构主体结构由底碗、移动产品碗电车,怜室、扩张室/过滤器住房。碗底部,产品容器和怜室充气硅垫片密封压缩空气检查传感器确保可靠的密封。 3. Product Filter The double structured bag filter in two pieces (in case request, stainless steel filter available) is inflatable silicon gasket sealed between the expansion chamber inner surfaces with compress air inspection sensor to assure the reliable sealing. A dust sensor is mounted on the exhaust piping and interlocked from control sys to secure the product safety during processing stage. 4. Exhaust AHU The exhaust dust collection filter is optionally designed for protect environment.

目录

不用于本产品目录。

看到所有Hywell机械公司的目录