- Industrial machines and equipment

- Furnace and Heat Treatments

- Hot air dryer

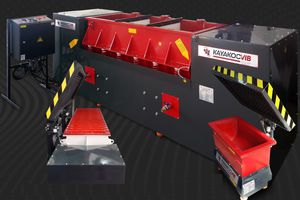

- KAYAKOCVIB MACHINERY ENGINEERING

- 爱游戏ayx守望先锋

- Catalogs

- News & Trends

- Exhibitions

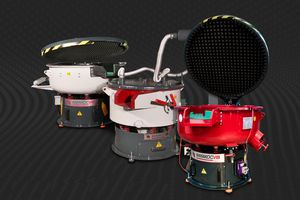

Hot air dryerDVM series

batch

coating

vibrating

添加到收藏夹”

Compare this product

Characteristics

- Technology

- hot air

- Batch/continuous

- batch

- Associated function

- coating

- 其他characteristics

- vibrating, high-performance

Description

DVM – Circular Type of Dryers series round vibratory dryer machines are used to remove water from the surfaces of products that are wet after deburring or polishing processes and to improve their corrosion resistance. ADVANTAGES OF DVM SERIES All metal and non-metal materials are rubbed and dried. It saves time and energy with minimum drying time thanks to heating coils. Hot air blow cover and dust absorption system are available as an option. Efficient ramp angle ensures the evacuation of all products. Vibration impact can be reduced or increased mechanically (by weight). Our high-performance vibration motor is long-lasting and minimizes your service costs. Long bowl life thanks to our abrasion-resistant elastomer type (90 Shore) polyurethane coating. Resistance to acidic environments with double layer epoxy paint. High efficiency with custom-design bowl and chassis height and spring design. Noise level is minimized with the optional Pneumatic Acoustic cover. As the vibration level can be adjusted with our speed-controlled panels, the most precise surface finishing is ensured on metal and non-metal surfaces. Remote control of the pneumatic ramp lever from the control panel is available as an option. DVM Series electrical panels can work in accordance with automation systems with PLC software. TVM Series can be integrated into the press lines that are continuously producing and work automatically. All parts used in our machines are selected according to EU standards. We have CE Certificate.

Catalogs

Product Catalog

20

Pages

其他KAYAKOCVIB MACHINERY ENGINEERING products

爱游戏ayx守望先锋

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.