- Hydraulics - Pneumatics

- Pump

- Wastewater pump

- NETZSCH Pumps & Systems

- Company

- 爱游戏ayx守望先锋

- Catalogs

- News & Trends

- Exhibitions

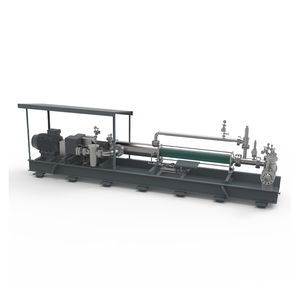

Progressive cavity pumpNEMO® BY

for wastewater

for chemicals

slurry

添加到收藏夹”

Compare this product

Characteristics

- Fluid

- for wastewater, for chemicals, slurry, for food products, oil, fuel, for biogas

- Operation

- with electric motor

- Priming

- self-priming

- Technology

- progressive cavity

- Mobility

- 静止不动的,mobile

- Domain

- for the petrochemical industry, industrial, for the chemical industry, for maritime applications, for wastewater treatment, for the food industry, for the pharmaceutical industry, for methanizers, for the mining industry, agriculture, for the paper industry, for the cosmetics industry, for hygienic applications

- Applications

- metering, transfer, for high-temperature applications, discharge, high-pressure, for high-pressure applications, process, drain, high-temperature, filling, chemical process, suction, conveying, for industrial applications

- Fluid specification

- for abrasive fluids, for solids-laden fluids, for low-viscosity fluids, for viscous fluids, for high-viscosity fluids

- 其他特征

- compact, with mechanical seals, close-coupled

- Flow

-

Max.:300 m³/h (10,594.40002 ft³/h)

Min.:0 m³/h (0 ft³/h)

- Pressure

-

Max.:24 bar (348.091 psi)

Min.:0 bar (0 psi)

Description

NEMO® BY Progressing Cavity Pump in Industrial Design The Solution to Convey and Accurately Dose a Wide Range of Media in Various Industries The BY block pump in industrial design can be used in , the and , but also in the as well as the sector for a wide variety of pressure-stable conveying or dosing tasks. From low-viscosity media to hardly flowing products, with or without solid content, shear-sensitive, sticky or abrasive, with the NEMO® BY progressing cavity pump even difficult substances can be conveyed gently and with low pulsation, regardless of fluctuations in pressure and viscosity. In addition, the progressing cavity pump guarantees flow rates proportional to speed with high dosing accuracy over the entire speed range. In block design with flanged drive, this NEMO® pump is especially compact and economical. Moreover, the NEMO® BY is distinguished by its low investment, operating and maintenance costs. Four are available for the various products and applications. 1 Rotor In wear- and corrosion-resistant designs including the wear-free ceramic rotor . 2 Stator Vulcanized into the tube with sealing on both sides in a variety of elastomers, plastics and metals. inlet with hopper-shaped opening for improved feed of the product into the conveying chamber. 2.2. Stator with iFD technology The consists of a two-part reusable housing with a polygonal profile and the NEMOLAST® elastomer housed within. The advantages of this new technology include a lower breakaway torque, higher efficiency, increased service life, simple and quick replacement, and environmentally friendly.

Catalogs

Other NETZSCH Pumps & Systems products

NEMO® Progressing Cavity Pump

Related Searches

- Netzsch pump

- Netzsch industrial pump

- Netzsch electric pump

- Netzsch stationary pump

- Netzsch water pump

- Centrifugal pump

- Netzsch chemical pump

- Netzsch self-priming pump

- Stainless steel pump

- Netzsch lubricant pump

- Submersible pump

- Netzsch transfer pump

- Netzsch compact pump

- Netzsch oil pump

- Netzsch pump for the chemical industry

- Impeller pump

- Netzsch metering pump

- Netzsch discharge pump

- Netzsch food product pump

- Top-mounted pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.