- 公司

- 爱游戏ayx守望先锋

- 目录

- 新闻和趋势

- 展览

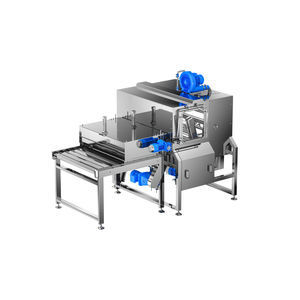

桨式混合机

批处理

粉

颗粒剂

添加到收藏夹”

这种产品比较

特征

- 技术

- 桨

- 批/连续

- 批处理

- 产品类型

- 粉、颗粒剂、气体,气体/液体,为土壤,为原油、燃料油、液化石油气

- 配置

- 垂直、水平、手机、手持,V

- 加载

- 仅需侧载,前期吃重

- 应用程序

- 水处理,食品工业,化学工业,制药工业,实验室,对于化妆品行业来说,塑料工业、采矿业、建筑业、石油工业、造纸工业、纺织工业、涂层技术

- 其他特征

- ATEX、高速、不锈钢、紧凑、多组分的,翻倍,重量,恒速,潜水器,磁驱动,环层,冷却器,锡膏,真空,高剪切,下端插入,分散剂,计量、加热/冷却相结合,气动,粉碎机,色母粒,节能,单级,变速,高压,低温,绞肉机,介质粘度液体,对于低粘度液体,多级,制粒机,与标准的鼓,聚四氟乙烯,四级,deagglomerating,飞行员,锥形,挤出机,旋转,clean-in-place (CIP) IP55,铸造用型芯砂,钢,,生物技术,自动,单轴,双轴的文丘里管类型、热交换器、高容量、比例、高性能、模块化、起重、触摸板控制,旋转碗,涡轮,thermo-regulated,活塞,两级,手册,低压,互换工作头,销,防爆,炊具,切割、腐蚀性液体、称重、液压、侧装,3-shaft, sterilize-in-place,粘度大,多轴,溶解,离心泵,精度高、捏和机、落地式、高温、螺旋

- 发动机功率

-

马克斯。7.5千瓦(10.2 hp)

最小值。5.5千瓦(7.5 hp)

描述

用于混合粉状或粉添加少量的液体。它解决了低一致性和死角造成不同比重的材料。当设备运行时,桨材料整个容器空间移动,所以材料是在瞬间失重状态,广泛交错对流和扩散,从而达到一个统一的混合效果。特色:1。能源节约和环境保护:降低能源消耗2。精致的设计:改善结构设计,容易清洗的设备,不容易产生残留3。高均匀性:该设备能保持优良的混合均匀性与CV值不超过4 2%。智能控制:每个处理步骤是由计算机控制,没有太多的人工干预5。易于维护:悬臂衬套叶片结构、维护更方便6。高效混合:单个批处理的混合时间是大约90秒的悬臂式套管式结构允许拆下检修门。 The design of quick replacement and easy cleaning ensures lowmaintenance requirements. The discharge port adopts a wedge-shaped structure. The fully open discharge door requires a short discharge time and brings higher efficiency. The unique shaft end seal design is adopted with adjustable preload.The discharge plate is supported and sealed at the dead point of the connecting rod to ensure no dust leakage during operation. The spacing between the paddle and the vessel can be adjusted, and the processing gap is between 2 and 4mm. These reduce material accumulation and mixing blind spots, bringing higher mixing efficiency.

目录

不用于本产品目录。

看到所有ONGOAL科技有限公司有限公司的目录