- 爱游戏ayx守望先锋

- 目录

- 新闻与趋势

- 展览

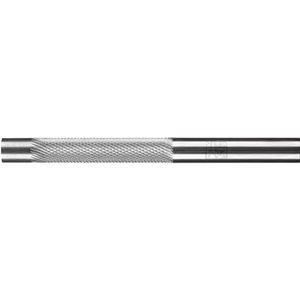

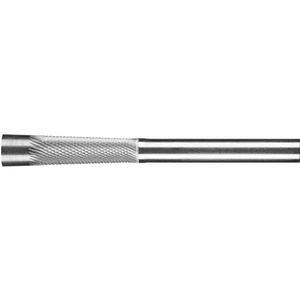

毛刺1306微

固体

完成

去毛刺

添加到收藏夹

比较这个产品

特征

- 建设

- 固体

- 类型

- 整理,毛刺,去毛刺

- 材料

- 碳化钨

- 处理材料

- 适用于铸铁、不锈钢、钛、钛合金、有色金属

- 其他特征

- 微

- 直径

-

6毫米(0.24英寸)

描述

具有MICRO切削的碳化钨毛刺是专门为精加工而设计的,用于安装研磨点的区域。与传统的研磨表面相比,它们具有更高的去除率和高表面质量。它们的工作振动低,噪音小。它们在整个工具寿命内保持其几何形状,非常适合手动和机器应用。几乎所有硬度高达68 HRC的材料都可以加工。1306 MICRO套装包含三个碳化钨毛刺,用于最常见的形状和尺寸的加工工作。坚固的塑料盒可以保护工具不被弄脏和损坏。优点表面质量高。与安装磨削点不同的是,由于磨损,它不会改变几何形状。适用于几乎所有68 HRC以下的材料。 The highly accurate concentricity enables impactfree working without creating chatter marks and the drive is subject to less wear. Recommendations for use Particularly well suited to finishing, for very fine cleaning work, corrections in tool and mould construction or for sharpening cutting tools. To prevent vibrations, place the tools on powerful drives with an elastically supported spindle wherever possible. Observe the recommended rotational speeds. Materials that can be worked Annealed cast iron Black annealed cast iron (GTS, GJMB) Bronze Case-hardened steels Cast iron Cast steel Cobalt-based alloys Grey/nodular cast iron (GG/GJL, GGG/GJS) Hardened, heat-treated steels over 1.200 N/mm² (< 38 HRC) Hard non-ferrous metal Nickel-based alloys (e.g. Inconell and Hastelloy) Stainless steel (INOX)

目录

没有此产品的目录。

查看PFERD的所有目录