- 爱游戏ayx守望先锋

- 目录

- 新闻与趋势

- 展览

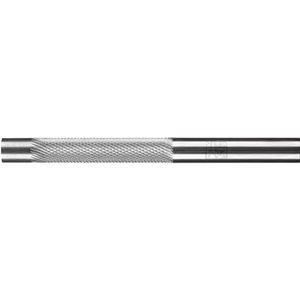

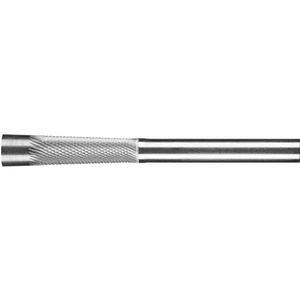

整体铣刀21155009

毛刺

去毛刺

碳化钨

添加到收藏夹

比较这个产品

特征

- 建设

- 固体

- 类型

- 毛刺,去毛刺

- 材料

- 碳化钨

- 处理材料

- 适用于不锈钢,有色金属材料,钛,钛合金

- 其他特征

- 圆锥、切削、机床

- 直径

-

8毫米(0.31英寸)

- 长度

-

73毫米(2.87英寸)

描述

碳化钨复制铣削毛刺由PFERD是完美的工具水平海拔,如焊缝。由于未切割区域,焊缝可以调整到周围表面的水平,而不会损坏。仿形铣削毛刺特别用于刀具和模具制造中的切削刀片和冲孔刀片的修复。碳化钨复制铣削毛刺与削减4是专为粗料去除。倒锥形旋转刀具,向刀柄锥形。倒锥WKN特别适合用于加工铝的冲孔工具。优点:刀具寿命长,表面质量高。未切割区域提供了最佳的轮廓引导和保护工件免受损坏。减少加工时间。使用建议为精确的轮廓导向,仿铣毛刺可与导向辅助工具一起使用。 Observe the recommended rotational speeds. To ensure costeffective use of burrs, use a higher rotational speed and cutting speed. Use burrs with a shank diameter of 6 mm with drives with a power output from 300 watts. Materials that can be worked Bronze Case-hardened steels Cast steel Cobalt-based alloys Hard aluminium alloys Hardened, heat-treated steels over 1.200 N/mm² ( 220 HB) Steels up to 1,200 N/mm² (< 38 HRC) Steels up to 700 N/mm² (< 220 HB) Titanium Titanium alloys Tool steels Applications Cutting out holes Deburring Leveling Milling Milling out Surface work Work on weld seams

目录

没有此产品的目录。

查看PFERD的所有目录