对刀触摸探头首先™

用于机床

触发

添加到收藏夹

比较这个产品

特征

- 类型

- 工具设置

- 应用程序

- 用于机床

- 其他特征

- 触发

描述

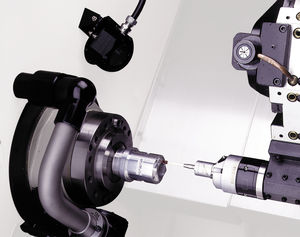

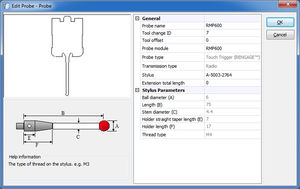

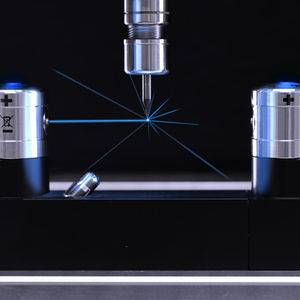

Primo无线电部件Setter是一种用于自动工件设置的触摸触发探头。它确定工件的确切位置,以便加工程序能够与之对齐。使用Primo无线电部件设置器有许多好处:与手动方法相比,部分设置时间减少了高达90%。工作偏移量会自动更新。消除了手动错误和部件设置的变化。减少材料的报废和返工。夹具成本降低。这些好处将为您节省资金,并为您在机器上获得更多的零件制造时间。该部分Setter安装在机器主轴上,并在测量周期中在机器控制下移动。当零件设定器的触控笔触碰到工件时,就会产生精确的触发信号。 This is sent, via radio transmission, to the machine's controller which records the position of the workpiece. Features and benefits: Repeatability of 1 μm 2σ to ensure results are the same every time a part is set. Robust and reliable in harsh machine tool conditions. Secure frequency hopping spread spectrum (FHSS) radio transmission to maintain a reliable connection.

目录

首先™系统

8

页面

HPPA高精度下拉臂用户指南

64

页面