线性测量接触探针首先™LTS

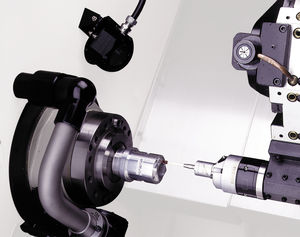

工具设置

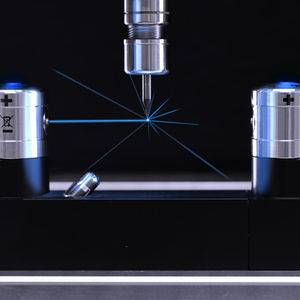

对机床

触发

添加到收藏夹”

这种产品比较

特征

- 类型

- 线性测量工具设置

- 应用程序

- 对机床

- 其他特征

- 触发,自动

描述

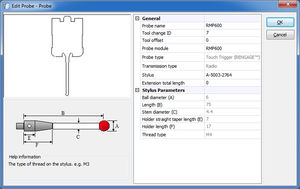

首先LTS是一个单轴工具setter,当与LTS应用软件一起使用,提供了许多好处。减少花费的时间设置工具90%与手工方法相比。自动更新工具偏移量。消除人为错误和变化设置工具。减少材料的废弃和返工。确定了工具,以便可以采取纠正措施。跟踪热机器和工具的变化首先LTS可以自行使用或与初初无线电部分Setter和接口来创建一个完全自动化的系统设置在您的机器上。LTS初独立于信用体系工作。首先LTS是如何工作的?大哥LTS时触发一个工具接触接触垫。 A trigger signal is sent to the machine tool controller via the hard-wired cable and the tool length is automatically calculated. Renishaw's LTS application software provides a set of unique cycles for the Primo LTS for tool setting, broken tool detection, thermal compensation and the set-up check. The Primo LTS is designed to operate within the machining environment, so it is resistant to swarf or coolant ingress and prevents false triggers due to shocks or vibration.

目录

首先™系统

8

页面